The control system design of five-axis repeater is a complicated and fine process, which involves many aspects of technology and knowledge. The following is a detailed explanation of the design of the five-axis repeater control system:

1. System architecture

The control system of five-axis repeater usually includes two parts: hardware and software. The hardware part mainly includes numerical control system, servo motor, sensor, actuator, etc. The software part includes control algorithm, kinematics model, human-computer interface and so on.

Second, hardware design

Numerical control system: The numerical control system is the core of the five-axis regenerator control system, which is responsible for receiving and analyzing the machining program, generating control instructions, and sending them to the servo motor in real time. Numerical control system usually adopts high performance processor and large capacity memory to ensure real-time control and accuracy.

Servo motor: The servo motor is the executive mechanism of the five-axis repeater, which drives each axis according to the predetermined trajectory according to the instructions of the numerical control system. Servo motor has the characteristics of high precision, high response speed and high reliability, which is the key to realize five-axis linkage control.

Sensors: Sensors are used for real-time monitoring of the motion state of each shaft and various parameters in the processing process, such as position, speed, force, etc. These sensors feed the monitoring results back to the CNC system for real-time adjustment and optimization.

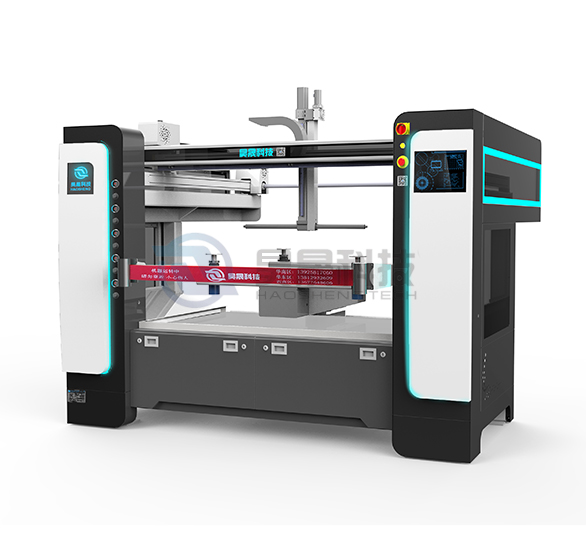

Actuator: Actuator includes bed, column, spindle box, workbench and other parts, which are connected to each other through high-precision guide rail, bearing and other connecting parts to form a stable processing platform. At the same time, two rotating axes (axis A and axis B) are cleverly designed and mounted on the headstock or workbench to achieve the rotation of the workpiece around the X and Y axes in the plane.

3. Software design

Control algorithm: Control algorithm is the key to achieve high precision machining. The commonly used control algorithms include interpolation algorithm, trajectory planning algorithm, velocity control algorithm and position control algorithm. These algorithms work together in the control system of the five-axis regenerator to achieve high-precision and efficient machining process.

Interpolation algorithm: responsible for converting discrete points in the machining program into continuous tool paths.

Trajectory planning algorithm: responsible for determining the path of the tool during machining.

Speed control algorithm: responsible for adjusting the speed of the tool according to the processing conditions and needs.

Position control algorithm: responsible for ensuring that the tool can accurately reach the specified position during machining.

Kinematic model: Kinematic model mainly studies the geometric relationship and motion law of each axis movement. In the machining process, the control system needs to control the movement of each axis through the computer according to the instructions in the machining program, so that the tool can cut according to the predetermined trajectory. At the same time, it is also necessary to consider the dynamic effects such as cutting force and vibration generated by the interaction between the tool and the workpiece, and adopt advanced dynamic models and control algorithms to reduce the impact of these dynamic effects on the machining process.

Human-machine interface: The human-machine interface is the window for the user to interact with the five-axis repeater. It usually includes input devices such as a touch screen, keyboard, mouse, and output devices such as a display. The user can input the machining program, set the machining parameters, and monitor the machining process through the human-computer interactive interface. At the same time, the human-computer interface can also provide fault alarm, fault diagnosis and other functions, which is convenient for users to maintain and maintain the equipment.

4. System optimization and debugging

Parameter optimization: After the design of the control system is completed, the parameters need to be optimized to ensure the stability and accuracy of the system. This includes the parameter setting of the servo motor, the parameter adjustment of the control algorithm, etc.

Debugging and testing: After the installation of the control system, it is necessary to debug and test. This includes no-load testing, load testing, accuracy testing, etc. Through debugging and testing, we can find and solve the problems existing in the system to ensure that the system can run normally and meet the design requirements.